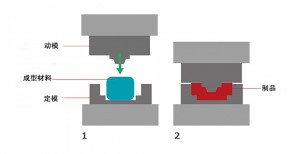

Mokhoa oa ho bopa o omileng

Alumina ceramicTheknoloji ea ho bopa e ommeng e lekanyelitsoe ho sebopeho se hloekileng le botenya ba lebota ho feta 1mm, karo-karolelano ea bolelele le bophara ha e fete lihlahisoa tse 4∶1.Mekhoa ea ho theha ke uniaxial kapa biaxial.Mochine oa khatiso o na le hydraulic, mochini oa mefuta e 'meli, e ka ba sebopeho sa semi-automatic kapa othomathike.Khatello e phahameng ea mochine oa khatiso ke 200Mpa, 'me tlhahiso e ka fihla likotoana tse 15 ~ 50 ka motsotso.

Ka lebaka la khatello e tšoanang ea stroke ea mochine oa hydraulic, bophahamo ba likarolo tsa khatiso bo fapane ha ho tlatsa phofo ho fapane.Leha ho le joalo, khatello e sebelisoang ke mochine oa khatiso oa mechine e fapana le palo ea ho tlatsa phofo, e leng ho tla lebisa habonolo phapang ea boholo ba shrinkage ka mor'a ho sintering le ho ama boleng ba lihlahisoa.Ka hona, kabo e tšoanang ea likaroloana tsa phofo ka mokhoa o omileng oa ho hatisa ke oa bohlokoa haholo bakeng sa ho tlatsa hlobo.Hore na palo ea ho tlatsa e nepahetse kapa che e na le tšusumetso e kholo taolong e nepahetseng ea likarolo tse entsoeng tsa alumina ceramic.Phello e phahameng ea phallo ea mahala e ka fumanoa ha likaroloana tsa phofo li le kholo ho feta 60μm le pakeng tsa 60 ~ 200 mesh, 'me phello e ntle ka ho fetisisa ea ho etsa khatello e ka fumanoa.

Mokhoa oa ho bopa ka grouting

Grouting molding ke mokhoa oa khale oa ho bopa o sebelisitsoeng holi-ceramics tsa alumina.Ka lebaka la ts'ebeliso ea hlobo ea gypsum, theko e tlase ebile e bonolo ho theha boholo bo boholo, likarolo tse rarahaneng tsa sebopeho, senotlolo sa ho bopa ha grouting ke ho lokisoa ha alumina slurry.Hangata ka metsi e le flux seaplane, 'me joale eketsa sekhomaretsi dissolving moemeli le binder, ka botlalo ka mor'a hore sila mokelikeli, 'me joale a tšela ka samente hlobo.Ka lebaka la ho khabisoa ha metsi ka capillary ea hlobo ea gypsum, slurry e tiisoa ka har'a hlobo.Hollow grouting, ka hlobo lerako adsorption slurry botenya ho fihlela ho hlokahala, empa hape lokela ho tšollela feteletseng slurry.E le ho fokotsa ho fokotseha ha 'mele, slurry e phahameng ea mahloriso e lokela ho sebelisoa ka hohle kamoo ho ka khonehang.

Li-additives tsa Organic li lokela ho ekeletsoa hoaluminium ceramicslurry ho theha lera la motlakase habeli holim'a likaroloana tsa seretse e le hore slurry e ka emisoa ka mokhoa o tsitsitseng ntle le pula.Ntle le moo, hoa hlokahala ho eketsa joala ba vinyl, methyl cellulose, alginate amine le li-binder tse ling le polypropylene amine, marenene a Searabia le li-dipersants tse ling, sepheo ke ho etsa hore slurry e loketse bakeng sa ts'ebetso ea ho bopa ha grouting.

Theknoloji ea sintering

Mokhoa oa tekheniki oa ho tiisa 'mele oa ceramic oa granular le ho etsa thepa e tiileng o bitsoa sintering.Sintering ke mokhoa oa ho tlosa sekheo pakeng tsa likaroloana tsa 'mele oa billet, ho tlosa khase e nyenyane le litšila tse tsoang linthong tse phelang, e le hore likaroloana li hōle hammoho le ho theha lintho tse ncha.

Sesebelisoa sa ho futhumatsa se sebelisetsoang ho chesa hangata ke sebōpi sa motlakase.Ho phaella ho tloaelehileng khatello ea sintering, ke hore, ntle le khatello ea sintering, chesang tobetsa sintering le chesang isostatic tobetsa sintering.Ho hatella ho chesang ho tsoelang pele ho ka eketsa tlhahiso, empa litšenyehelo tsa thepa le hlobo li phahame haholo, ho phaella ho bolelele ba sehlahisoa se lekanyelitsoe.Hot isostatic pressure sintering e amohela mocheso o phahameng le khase e phahameng ea khatello e le mokhoa oa ho fetisa khatello, o nang le monyetla oa ho futhumatsa seaparo ka mahlakoreng 'ohle,' me o loketse ho cheka lihlahisoa tse rarahaneng.Ka lebaka la sebopeho se ts'oanang, thepa ea thepa e eketseha ka 30 ~ 50% ha e bapisoa le sintering e batang.10 ~ 15% e phahame ho feta sintering e tloaelehileng e chesang e chesang.

Nako ea poso: May-12-2022