Mehato ea tlhahiso ea lihlahisoa

Tokisetso ea lintho tse tala

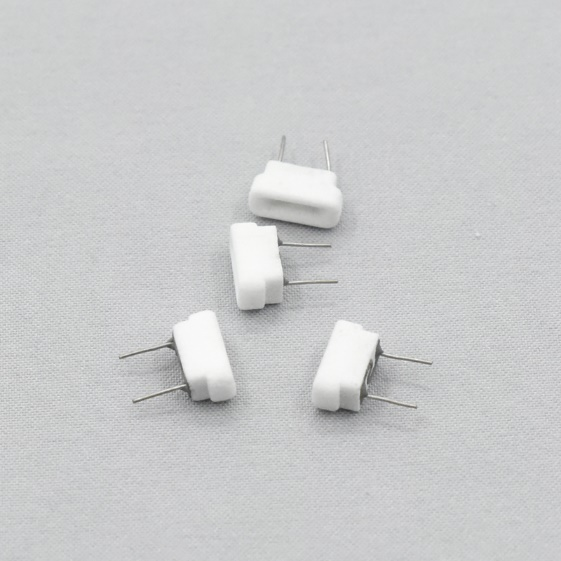

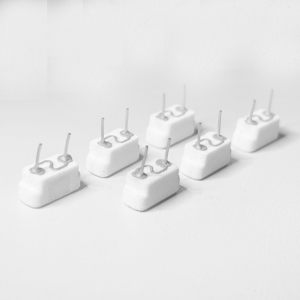

Hot Compression Molding

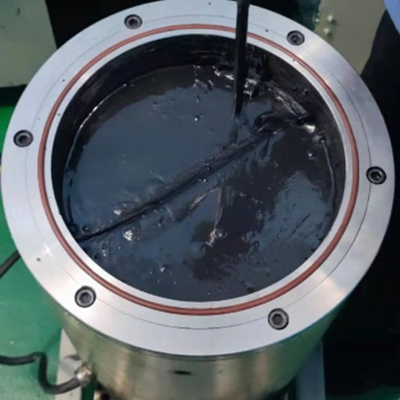

Sintering e phahameng

Potoloho e hatisitsoeng

Mocheso o phahameng oa vacuum sintering

Ho lemoha ho paka

Melemo

Sehlahisoa se chesoa ho 1050 ℃. Ha ho metsoako e kotsi e setseng mme e fetisa setifikeiti sa FDA.

Sehlahisoa se entsoe ka vacuum sintered.Ha ho lerōle holim'a metsi.Ha ho kotsi ea ho hema matšoafong.

Matla a ceramic ho fihla ho 60N.E sa senyeheng le ho fihlela litlhoko tsa kopano.

Potoloho e teteaneng ea khatiso ea filimi e chesa ka potlako ebile e tsitsitse.Ha ho bonolo ho hlahisa cheso e tšoenyehileng.Bophelo bo feta 350 puff.

Ceramic ha e na tšepe.E ke ke ea itšoara ka mokelikeli o kang oli ea mosi 'me e ke ke ea fetola' mala ha e le polokelo e tloaelehileng.

Potoloho ea Ceramic le e hatisitsoeng e lumellana haholo.E ka etsa atomize ka botlalo le ho latsoa hamolemo.

Kopo

E-cigarette

E-cigarette

Atomizer ea boemo ba bongaka

Sefehla moholi

Lintlha tsa theknoloji

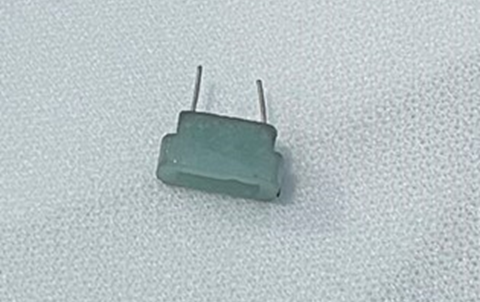

| Mohlala No. | Porous ceramic atomizing core |

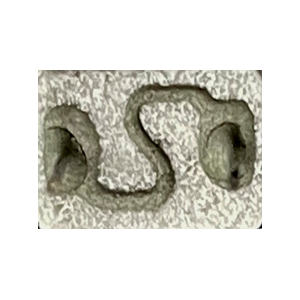

| Sekoti: | 28-32nm |

| Porosity: | 55% |

| Sekhahla sa Wicking: | >20mm/sec |

| Matla a Ceramic: | >60N |

| Mocheso ha ho futhumatsa: | 220-250 ℃ |

| Bophelo ba mosebetsi: | 350puff (Matla: 6w) |

| Tšebeliso ea oli ea mosi bakeng sa puff | >6mg (Data e fapaneng e nang le libomo tse fapaneng tsa mosi) |

Tlhokomeliso: Kaha lihlahisoa li lula li nchafatsoa, ka kopo ikopanye le rona bakeng sa lintlha tsa morao-rao.

Indasteri e sebetsang

Indasteri ea elektronike le ea motlakase

Indasteri e ncha ea matla

Indasteri ea masela

Lisebelisoa tsa bongaka

Indasteri ea Lik'hemik'hale