Phello eamicroporous ceramic atomizing mantlhaka mosi oa elektroniki

1. Porosity vs. matla

Khanyetsano ea pele ea li-ceramics: ho fokotseha ha matla ho tla etsa hore li-ceramics li theohe phofo, qetellong ea hoetla, kopano e atisa ho arohana, e leng se etsang hore ho fokotsehe chai.

2. Pore boholo vs. oli conductivity

Boholo ba pore eali-ceramics tse nyaneha e lekane ho microstructure mme ha e na geometry e tloaelehileng.Boholo ba pore bo boholo kapa bo nyane.Phallo ea li-ceramics tse nyane hangata e bua ka kabo ea nako, mocheng o tsoelang pele oa phallo, sebaka se tlase sa palo ea oli se bapala karolo ea makhaola-khang, palo ea oli e lekana le lisekoere tsa lesoba, sekoti se seholo, kapele oli.

3. Sekoti khahlanong le sebopeho

Ntle le ho ama sekhahla sa conduction ea oli, aperture ke pontšo e 'ngoe ea bohlokoa ke tatso.Ha atomizing, haeba oli ea mosi e le karoloana e khōloanyane ea atomized, phallo ea mouoane e thehoa e batla e le mahoashe, 'me marotholi a thehoa ka mor'a hore condensation e be kholoanyane, e nang le tatso e batlang e le matla le e thabisang.Ha lesoba le le lenyenyane, ho phalla ha mouoane ho entsoe ka "atomization" ea oli, ho ntlafala ha likaroloana tsa aerosol, phello e ntle ea ho hasana, e ts'oanang, tatso e bonolo.Ka hona, ha lesoba la tataiso ea oli le le lenyenyane, ho ba betere.

Tlhahlobo ea lintlha tse bohloko tsamicroporous ceramic atomizing mantlha

Thepa ea ho tsamaisa oli le matla a lirafshoa li ke ke tsa eloa hloko, kahoo ho hlokahala lesoba le leholo ho fumana matla a lekaneng a ho tsamaisa oli.Sekoti se seholo se tla etsa hore lesoba la ceramic le fokotsehe;Tatso e ntle ea motheo ea atomizing ea ceramic e hloka sebaka se senyenyane se lekaneng;Matla a Ceramic, conduction ea oli, litlhoko tsa tatso bakeng sa aperture li fapane haholo.Li-ceramics likarolong tsena tse tharo tsa ts'ebetso ha li khone ho ela hloko ka bobeli, li hanyetsana.Empa motheo oa motheo oa ceramic atomization, ho kenyelletsa le tlhōlisano ea mantlha ea e-cigarettes ke tatso, e leng ts'ebetso e lokelang ho tiisetsoa pele.Ka hona, boholo ba pore bo nyane ho lekana ho fana ka oli e lekaneng.

1. Boholo bo botle ba pore le porosity e phahameng:

Theknoloji ea ho lokisa thepa ea Nano ceramic, laola boholo ba likaroloana le motsoako oa phofo ea ceramic, fumana sebopeho se setle sa pore le kabo ea boholo ba pore, qoba tahlehelo ea matla e bakoang ke li-pores tse kholo.Ntlafatsa ho ts'oana ho ts'oana ha phofo ea ceramic, eketsa lethal dose ea ho etsa pore, 'me u fihlele porosity e phahameng.

2. Leseli lali-ceramics tse nyane:

Fetola foromo ea lintho tse bonahalang, ntlafatsa matla a ka hare a thepa ea ceramic microporous, moralo o nepahetseng le ho laola mocheso oa sintering, ho fumana tekanyo e ntle ea sintering, ho finyella tekano pakeng tsa porosity le matla.Moralo o nepahetseng oa liindasteri o tla fihlela tekano lipakeng tsa matla, porosity le aperture, ho fihlela phepelo e nepahetseng ea oli le phello ea tatso.

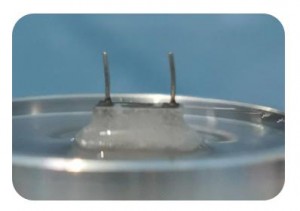

3. Ntlha e 'ngoe e bohloko ea mokokotlo oa ceramic ke mouoane oa nicotine le mohloli oa oli ea sakerete.E hloka tikoloho e tsitsitseng ea mocheso, 'me kabo ea mocheso ha e lekane.E le ho phehella tatso ea ho qetela, ts'ebetso ea terata e futhumatsang ea hlokahala bakeng sa ts'ebetso e ntle le ho e etsa, ka hona, mokhoa oa hajoale oa nts'etsopele ea microporous ceramic atomization core ke ho etsa metallization e hlophisitsoeng holim'a substrate ea ceramic.Ho na le mekhoa e mengata ea ho etsa metallize bokaholimo ba ceramic, 'me e' ngoe ea litheknoloji tse atileng haholo tse sebelisoang hona joale ho lisakerete tsa elektronike ke khatiso e tenya ea filimi, e ts'oanang le pente ea solder ea PCB.Ts'ebetso ena ha e sebelisoe feela libakeng tse bataletseng, empa hape le libakeng tsa 3D.

Nako ea poso: Jul-19-2022